Wet wipes Packaging Machine

Single Wet Wipes Towel Tissue Packaging Machine

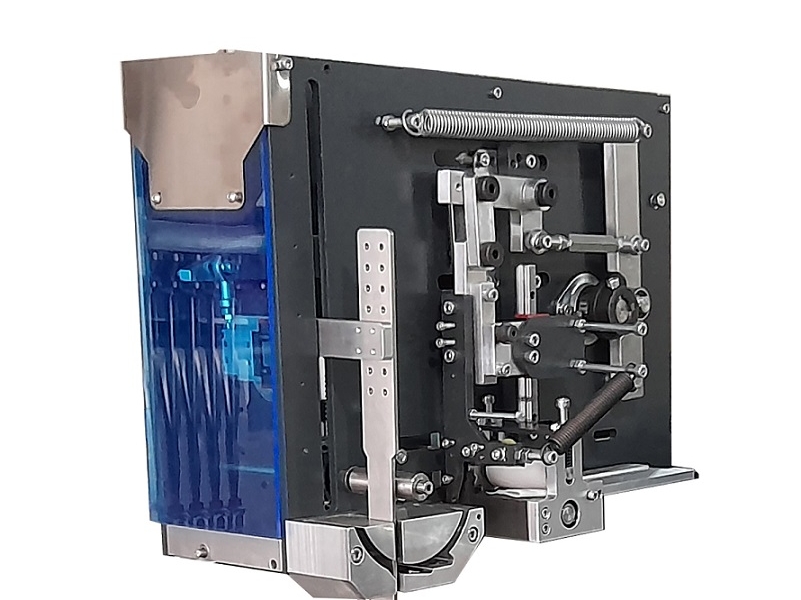

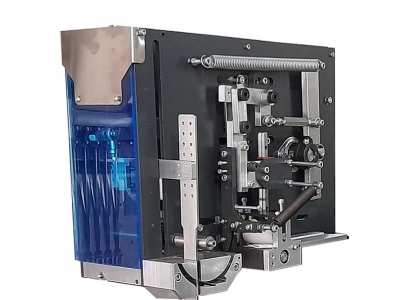

Aypamak Wet Single Towel Tissue Packaging Machine is known for its quality consistency, simplicity, competitiveness and quality. It is easy to use, economical, cost-effective and reliable. The automatic Wet Single Towel Tissue Packaging Machine produced by our company has adopted international technology. With the synthesis of the current packaging technology, stable design, efficient and stable operation, it can package your products in various sizes. Aypamak Hp-100-W Wet Single Towel Tissue Packaging Machine is the optimum choice for economical packaging. Our company provides cologne wipe packaging service and spare parts guarantee.

Aypamak Wet Single Towel Tissue Packaging Machine is known for its quality consistency, simplicity, competitiveness and quality. It is easy to use, economical, cost-effective and reliable. The automatic Wet Single Towel Tissue Packaging Machine produced by our company has adopted international technology. With the synthesis of the current packaging technology, stable design, efficient and stable operation, it can package your products in various sizes. Aypamak Hp-100-W Wet Single Towel Tissue Packaging Machine is the optimum choice for economical packaging. Our company provides cologne wipe packaging service and spare parts guarantee.

The Wet Single Towel Tissue Packaging Machine is a single line filling and packaging machine designed for the packaging of cologne essence and nonwoven towels. Fully automatic horizontal wet wipes machine fills products in sachet package type. No collar form is required. It first unloads the laminated, printed, rolled foil according to the packaging speed of the machine. During the pulling by an automatic servo motor system, the foil is folded in half. In the next drawing pitch, it performs sub-welding, unpacking, vertical welding and cutting operations in pitch order during drawing. It is pulled mechanically to the desired length by means of servo motor pulling system. When it comes to the filling pitch during drawing, the liquid weighed into each package is thrown into the product by a volumetric filling pump through the nozzle.

In coil form, it doubles the packaging material with a minimum width of 100mm and a maximum width of 300mm. Wet wipes packages with a minimum height of 60mm and a maximum height of 150mm when folded. It consists of functional groups specified to make packages with a width of 60 mm to 70 mm as a general standard, and Wet Cologne Wipes suitable for different package sizes, if desired.

-

Machine Main Body

It is manufactured from profile steel material as standard. It is coated with static baked paint. It has long-lasting, corrosion-resistant, dust-proof and food-compatible features. The machine plate and the work tray are made of stainless sheet cladding. -

Machine Main Motorized

0.75 kW Gamak Motor and Yılmaz Gearbox are used. Domestic production of the motor and reducer used is preferred. It provides ease of supply in case of any adverse situation in long-term production processes. Energy savings and maximum power are aimed with the reducer used. SCHNEIDER brand driver is used as Main Motor Driver. -

Drive Cams

A special steel material is used for long-lasting use. Hardened and specially fabricated cams reduce long-term operating costs to zero. -

Coil Opening Stand There is an automatic motorized foil opening system synchronized according to the machine speed. 0.18 kw Gamak Motor and Yılmaz Gearbox are used. Domestic production of the motor and reducer used is preferred. It provides ease of supply in case of any adverse situation in long-term production processes. Energy savings and maximum power are aimed with the reducer used.

There is an automatic motorized foil opening system synchronized according to the machine speed. 0.18 kw Gamak Motor and Yılmaz Gearbox are used. Domestic production of the motor and reducer used is preferred. It provides ease of supply in case of any adverse situation in long-term production processes. Energy savings and maximum power are aimed with the reducer used. -

Sub-welding Mechanism

Bottom edge welding of the Double Folded material is done. By ensuring that the mechanism does not come into contact with the material, at the end of the operation, a package with 3 sided adherents is taken. The heat level is controlled by independent ENDA brand domestic production thermostats belonging to the lower sealing jaw. There are Dc 48 volt domestic production resistors in the bonding jaw. -

Unpacking mechanism

prepares the middle of the doubled material for filling. The nonwoven tissue, which is folded in 2 or folded in 3, drawn between the foil spaced for filling, is inserted into the package by means of a ruler. -

Towel opening and transverse folding stand system

A motorized reducer automatically opens the rolled nonwoven towel with a width of 90mm to a maximum of 250mm and a thickness of 30-200 gsm in coil form. 0.18 kw Gamak Motor and Yılmaz Gearbox are used. Domestic production of the motor and reducer used is preferred. It provides ease of supply in case of any adverse situation in long-term production processes. Energy savings and maximum power are aimed with the reducer used. Guide ruler descends for filling into the package after cutting and folding the towel, which is formed 4, 6 or 8 horizontally.

A motorized reducer automatically opens the rolled nonwoven towel with a width of 90mm to a maximum of 250mm and a thickness of 30-200 gsm in coil form. 0.18 kw Gamak Motor and Yılmaz Gearbox are used. Domestic production of the motor and reducer used is preferred. It provides ease of supply in case of any adverse situation in long-term production processes. Energy savings and maximum power are aimed with the reducer used. Guide ruler descends for filling into the package after cutting and folding the towel, which is formed 4, 6 or 8 horizontally.

-

Handkerchief Lengthening, Cut-to-Length, 3 Folding Ruler Lowering Mechanism

The nonwoven, folded towel rolled into a bobbin is drawn to the desired length with a servo motor mechanism, cut from 90mm to 180mm and folded into 3 folds. The towel and nozzle go down into the package. Wipe pulling Delta brand Servo motor and driver are used.

Vertical welding System

Vertical welding of the shaped material is done. The heat level is controlled by independent ENDA brand domestic production thermostats belonging to the Vertical gluing jaw. There are DC 48 volt Turkish production resistors in the bonding jaw. -

Top Edge welding System

Upper welding of the material that is formed is done. The heat level is controlled by independent ENDA brand domestically produced thermostats and SS Relays belonging to the upper sealing jaw. There are Dc 48 volt domestic production resistors in the bonding jaw. -

Servo Motorized Length Pulling System

It pulls the package length for printed and unprinted materials. Automatic bag size adjustment is made on the screen. Working with or without photocell is suitable. Delta brand Servo motor and driver are used. Holding and Pulling grippers Mindman Brand are used. -

Cutting System

Sequential filled packages are cut and single packages are dropped. The cutting system and blades are made of long-life tool steel against blunting. A special steel material is used for long-lasting use. Hardened and specially processed knives reduce long-term usage costs to zero. Both surfaces of the blades are suitable for use alternately for cutting purposes. -

Plc Control System and Touch Screen

It is controlled by a 7” DELTA brand touch operator panel with an easy-to-understand menu. Plc software is specific to our company and has been shaped in line with the demands of our customers. It is a parametric software suitable for different production processes. It is easily synchronized by the operator according to the correct working processes. The package size and speed settings of the cologne wet wipes packaging machine can be controlled by a PLC program suitable for parametric flexible operation with screen intervention.

It is controlled by a 7” DELTA brand touch operator panel with an easy-to-understand menu. Plc software is specific to our company and has been shaped in line with the demands of our customers. It is a parametric software suitable for different production processes. It is easily synchronized by the operator according to the correct working processes. The package size and speed settings of the cologne wet wipes packaging machine can be controlled by a PLC program suitable for parametric flexible operation with screen intervention. -

welding Jaw Resistances

The heat level is controlled by 3 independent ENDA brand domestic production thermostats belonging to the lower bonding, vertical bonding and upper bonding jaws. There are Dc 48 volt domestic production resistors in the bonding jaw. The resistors are steel wired. It is designed with steel cable in order not to break against Machine Movement and to have a long life. By using 48v DC electrical energy with the locally produced Transformer attached to the machine as hardware, energy saving and occupational safety compliance are ensured. 3 independent ENDA branded domestic production Solid State Relays belonging to the bonding jaws were used. -

Other electrical materials used

Motor protection switch, Contactor, Fuses, Main motor driver SCHNEIDER brand products were preferred. DC24 volt Air Valves are Mindman brand. Relays are German made PHONIX brand.

|

Machine Weight

|

550 kg.

|

|

Machine Dimensions

|

230x90x350cm.

|

|

Electricity requirementl

|

5 kw.

|

|

Compressed Air

|

6-8 bar. 300 liter filtered compressed air is used.

|

|

Package Depth

|

Minimum 50mm. Maksimum 150mm.

|

|

Towel Width

|

90mm.-250mm between witdh Nonwoven

|

| Towel Cut Length |

90 ile 180mm between

|

|

Packing Capacity

|

Per Minute 90-70 Piece

|

|

Package Width

|

60mm ile 70mm standard width and other special sizes

|

|

Packaging Material

|

Laminated aluminum, metallized, opp, pe foil coil

|

Mechanical Warranty: 2 years

Electronic Warranty: 1 Year

Userguide

Free Training and Installation Service

24/7 Whatsapp Help

Electrical Circuit Diagram

Daily, end-of-work, weekly, monthly, 6-monthly and annual maintenance is done.

The machine is 100% domestic production and our own production. Our sales prices for the Refreshing Wipes packaging machine, our costs may change in line with the current market conditions. You can get information about our current prices from the 24/7 whatsapp line.

Electronic Warranty: 1 Year

Userguide

Free Training and Installation Service

24/7 Whatsapp Help

Electrical Circuit Diagram

Daily, end-of-work, weekly, monthly, 6-monthly and annual maintenance is done.

The machine is 100% domestic production and our own production. Our sales prices for the Refreshing Wipes packaging machine, our costs may change in line with the current market conditions. You can get information about our current prices from the 24/7 whatsapp line.

| Liquid filling |

Notch Mold

|

|

Guillotine Cutting System

|

|

|

Molded cutting system

|

It is fast and efficient. They are systems that do not require a lot of personnel and minimize labor costs.

It ensures efficient use of limited resources.

It plans consumption in accordance with human health.

It ensures efficient use of limited resources.

It plans consumption in accordance with human health.

All processes such as software, electricity, automation, service, spare parts, production are done within our company. In the face of problems that may occur in the machines in these matters, our company intervenes without interrupting the production. In these areas, our company does not find it appropriate to work with suppliers. For the continuity of its customers' production processes, our company always offers itself an experienced, knowledgeable and prepared problem solving approach.

It provides the opportunity to stock up as much as consumption needs.

It provides fast sales and high profitability in the short term for the business. The wholesale product is sold at the retail price

It provides fast sales and high profitability in the short term for the business. The wholesale product is sold at the retail price

Among the products produced by Aypamak Wet Wipes Machine; They are ideal packaging machines for the cosmetics, cleaning and personal care industries. With the servo motorized wipe pulling system, wet wet wipes with a deodorant, Glasses Wipes, TV screen cleaning cloth, mobile phone screen cleaning wipes, etc. can be produced. The products produced by the Disposable Alcohol Wet Wipes Machine stand out with their high sealing power, reliability and appearance. Makes 60-70 mm wide wipes as an average standard. It is possible to pack wipes in other non-standard sizes.

In the fully automatic wet wipes packaging machine, OPP, PE, Aluminum, Laminated Coated paper can be used in roll or coil form as packaging material. It is now possible to work without wastage with the automatic package pulling system with Servo Motor. Packaging material can be packaged using packaging material between 40 microns and 120 microns in thickness.

The purchase of raw materials and semi-finished products such as iron, steel, aluminum, stainless, electrical, automation materials, pistons, bearings, which we use in production, changes in parallel with the daily exchange rates. You can quickly get up-to-date price information from our Whatsapp line.

The machine belonging to our company, has its own compact design. It is suitable for the application of filling systems for the purpose of filling liquid, powder and granular products on our machine. In this regard, it offers a design suitable for optionality. Coffee, cocoa, soup, powdered drinks, instant soup, tomato paste, fruit juice, detergent etc. It is made completely thanks to the filling systems that can be integrated on the products. Horizontal Filling Machine is a fully automatic sachet type filling and packaging machine for powder and granular products. Aypamak Packaging Machines are ideal packaging machines for the food, pharmaceutical, cosmetic and fine chemical or agrochemical industries with the Liquid Filling Pump integrated into the fully automatic wet wipes packaging machine. With its volumetric filling system, Ketchup, Mayonnaise Powder, Disinfectant, Fruit Extract Syrup, Honey, Jam, Chocolate, Medicine, Shampoo etc. The products produced by the machine stand out with their high sealing strength, reliability and appearance. Automatic filling from 1 ml up to 40 ml

stock delivery

It provides the packaging of granular or liquid products by integrating the liquid or volumetric dosing system into the wipes packaging machine. The wipes packaging machine is based on quality and speed, and uses the necessary designs and up-to-date technologies in order to be able to pack the products untouched. Aypamak Makine has developed its entire infrastructure on "packaging machine" since the day it was founded, has proven its difference in the market in packaging machines and automation systems and strengthened its position.