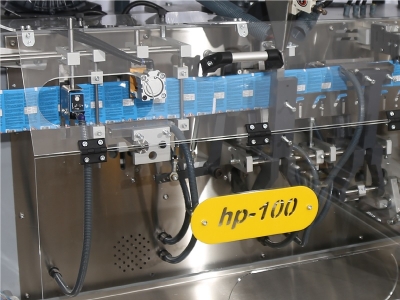

Powder Filling Machine

Powder Filling Machine

Full Otomatic Powder Sachet Filling packaging Machine

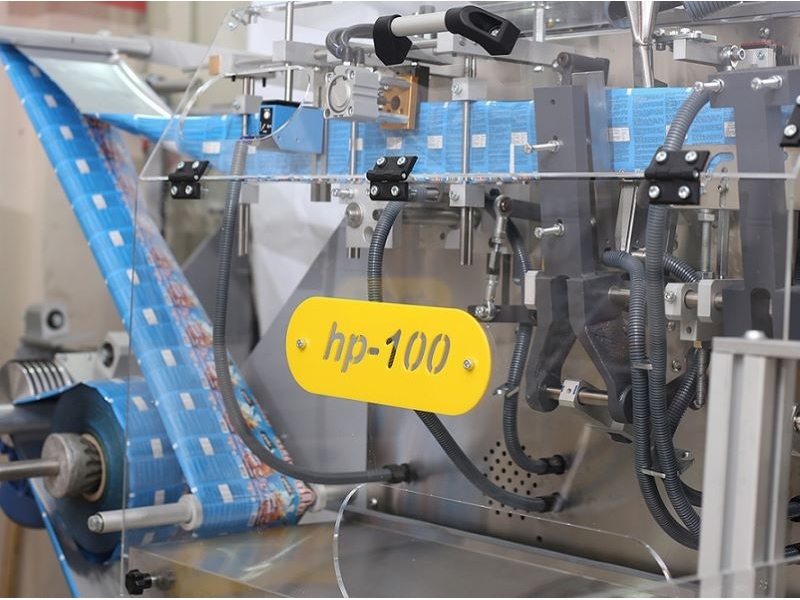

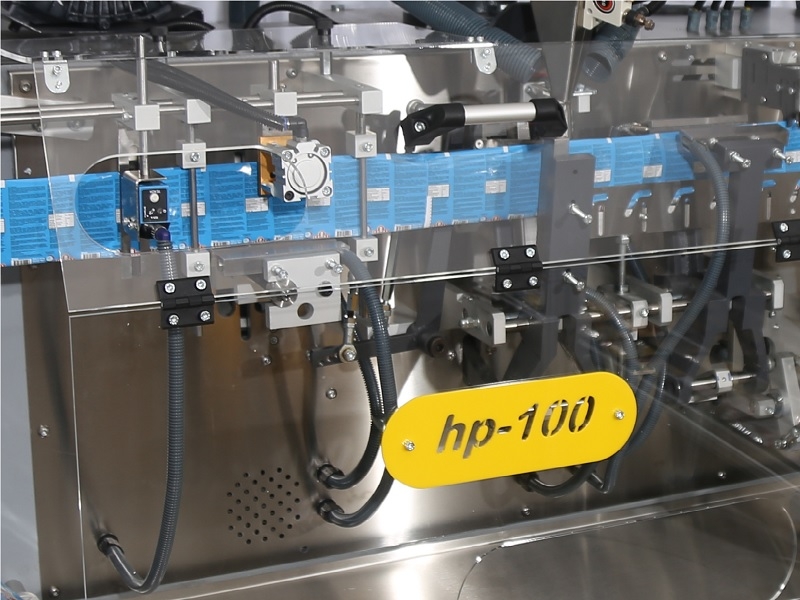

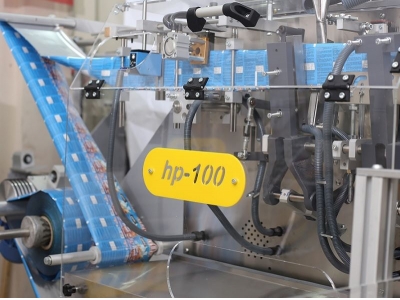

Powder filling machine is a single line packaging machine designed for horizontal packaging of powder products. It first unloads the laminated, printed, rolled foil according to the packaging speed of the machine. Powder filling packaging machine does not need any Collar form. During the pulling of the package by an Automatic Servo Motorized system, the foil is folded in half. In the next drawing pitch, it performs sub-welding, unpacking, vertical welding and cutting, respectively, during drawing. Servo motor pulling system pulls up to the desired length mechanically. When it reaches the filling pitch during drawing, the weighed product is thrown into the package with a screw. It is fast and efficient. They are systems that do not require a lot of personnel and reduce labor costs. It ensures efficient use of limited resources. It helps to make consumption in accordance with human health. It provides the opportunity to stock up as much as consumption needs. For the business, it provides fast sales and high profitability in the short term.

Servo System Powder Filling Packing Machine

Extraction and Filling settings can be adjusted to different Package sizes. The Filling System has a design that can be easily adapted to the packaging of different product groups. The machine is capable of packaging powder products, and the design of the machine is suitable for filling and packaging liquid or granular products if needed. Sachet packages with 4 sides glued and filled with product are taken. If desired, sachet packages that have been ironed on 3 sides can be purchased.

Sachet Powder Filling with Screw Servo System

The product is weighed as a Servo Motor Screwed Powder Filling. When the guide funnel descends into the package, the filling is done between 1 gram and 60 grams with 3% accuracy. Thanks to the Servo Motor system, the filling screw dosing with the same precision every time at the filling time. Powder filling amount and speed control required for the product are adjusted on the touch screen. The most important feature of the Servo Motor system is that it can repeat the same movement every time with near-zero escape. They are the necessary technological systems for the filling of products that require high precision. In the Powder Filling and Packaging Machine, when the angular filling time comes, the Servo Motor Filling System fills the product into each package at the same rate each time, with a deviation close to zero. This deviation is a very low rate of 3 out of 100. It easily meets the speed and torque required during filling. At the same time, another most important feature of the Servo Motorized Filling System is that it is long-lasting, maintenance-free and cost-free systems. There is no maintenance cost compared to Servo Motorless systems in the market. With this feature, although the Servo Motorized Filling System affects the purchase prices of the machine positively, it will pay off in the production phase many times over. Product fluidity and density are important for quality dosing.

Packet Pulling System with Servo Motorized

Package widths: While the pulling system is in the standard back-of-knife position, the lowest 50mm packages can be pulled, while different package lengths can be drawn up to a maximum width of 120mm. Different size changes can be easily passed through the touch operator screen. (50mm,,,,,?,,,,,,120mm). In order to take packages in smaller sizes, the Servo Motorized Pulling System has the opportunity to reduce up to 30mm, the lowest size that can be filled when it is taken before the blade. It performs the repeatable high precision package pulling of the Servo Motor quickly and precisely. It pulls each packet with the same width. In photocell material, it applies the signal given by the speckle sensor in the fastest microseconds. The most important criteria for quality packaging and Servo Pulling system are directly proportional to dusting of the product, adhesion properties of the packaging material, the storage of the product by the packaging and the quality of the packaging speckle printing.

Package widths: While the pulling system is in the standard back-of-knife position, the lowest 50mm packages can be pulled, while different package lengths can be drawn up to a maximum width of 120mm. Different size changes can be easily passed through the touch operator screen. (50mm,,,,,?,,,,,,120mm). In order to take packages in smaller sizes, the Servo Motorized Pulling System has the opportunity to reduce up to 30mm, the lowest size that can be filled when it is taken before the blade. It performs the repeatable high precision package pulling of the Servo Motor quickly and precisely. It pulls each packet with the same width. In photocell material, it applies the signal given by the speckle sensor in the fastest microseconds. The most important criteria for quality packaging and Servo Pulling system are directly proportional to dusting of the product, adhesion properties of the packaging material, the storage of the product by the packaging and the quality of the packaging speckle printing.

Technicial Specifications

|

MODEL

|

Aypamak HP100P

|

| FUNCTION | Fully Automatic Screw Powder Filling and Horizontal Packing Machine |

|

WEIGHT

|

400 kg.

|

|

DIMENSIONS

|

Ön 230x En 90xBoy 230cm.

|

|

ELECTRİC NEED

|

5 kw. Trifaze Electric

|

|

COMPRESSED AIR CONSUMPTION

VALVE PNEUMATIC |

6-8 bar. Filtered compressed air 6-8 bar. Filtered compressed airMindman Solenoid Valve and Pistons |

|

PACKAGE

TYPE SIZE WIDTH PHOTOSEL

|

Sachet type package with 3 or 4 sides adhered is taken. Sachet type package with 3 or 4 sides adhered is taken.Min:50mm. Max:160mm. Size between witdh 55mm-120mm between witdh It works according to the speckle system on printed materials. Made in Germany ZICK spot sensor is used. speckle signal sensitivity and easy speckle introduction easy quality |

|

FILLING

WEIGHT DUST PRODUCTS |

Products between 1 gram and 60 grams are filled. Products between 1 gram and 60 grams are filled.Powder beverage, Coffee, Cocoa, Nescafe, Baking Powder, Spices, Food Supplements, Carbonate, Sugar, Salt, Chalogen, Vitamin, etc. products. They are ideal packaging machines for the Food, Pharmaceutical, Powder beverage, Spices, Cosmetics, cleaning, personal care industries. The products produced by the Powder Packaging machine stand out with their high sealing power, reliability and appearance. |

|

PACKAGING

CAPACITY |

It differs between 90 and 40 pieces per minute, depending on dusting and weight. (per minute; 10 grams 80 pieces, 50 grams 40 pieces)

|

|

MAIN DRIVE |

Schneider Driver Schneider DriverTurkish Yılmaz Geared Motor A special steel material is used for the long-lasting use of the powder filling packaging machine. Hardened and specially fabricated cams reduce long-term operating costs to zero. |

|

CUTTING

SYSTEM |

The cutting system and blades are made of long-life tool steel against blunting. A special steel material is used for long-lasting use. Hardened and specially processed knives reduce long-term usage costs to zero. Both surfaces of the blades are suitable for use alternately for cutting purposes.

|

|

FILLING

|

Servo Motor Screw Precision Powder Filling System Servo Motor Screw Precision Powder Filling System |

|

PACKET PULL

|

Servo Motorized lineer Sistem

|

|

WELDING

RESISTANCE THERMOSTAT SSR |

The heat level is controlled by 3 independent ENDA thermostats and SSRs of the lower welding, vertical bonding and upper welding jaws.

There are Dc 48 volt domestic production resistors in the welding jaw. The resistors are steel wired. It is designed with steel cable in order not to break against Machine Movement and to have a long life. The machine is equipped with a locally produced Transformer and 48v DC electrical energy is used to provide energy saving and occupational safety compliance. |

|

CONTACTOR

FUSE

RELAY

|

Schneider Contactor and Motor Protection Schneider Contactor and Motor ProtectionSchneider Insurance Phonix Relay |

|

FOIL OPENING

PACKAGING

|

Automatic Motorized Foil Opening Automatic Motorized Foil OpeningMin:100mm max:300mm between witdh OPP, PE, Aluminum, Metallized, Laminated Coated paper in roll or coil form A 3-layer laminated foil material with a thickness between 40 and 120 micron grams/m2 is used. |

|

MIXER MOTOR

|

Automatic Mixer Motorized Filling

|

| MACHINE BODY | It is manufactured from profile steel material as standard. It is coated with static baked paint. |

|

SCREEN PLC SOFTWARE

|

It is controlled by a 7” DELTA brand touch operator panel with an easy-to-understand menu.

Parametric Aypamak HP100P software is available. Plc software is specific to our company and has been shaped in line with the demands of our customers. It is parametric AYPAMAK HP100 software suitable for different production processes. It is easily synchronized by the operator according to the correct working processes. The package size and speed settings of the powder packaging machine can be controlled by a PLC program suitable for parametric flexible operation with screen intervention. |

|

GUARANTEE

|

Mechanical and Electronic 1 Year

|

|

DOCUMENT

|

Detailed User Manual

Electrical Circuit Diagram |

|

OPTIONAL

EQUIPMENT |

Date Coding, Feeding Auger, Exit Conveyor, Volume Filling System, Liquid Filling System, Notch Mold, Guillotine Cutting System, Molded Cutting System

|

|

EDUCATION, INSTALLATION

SERVICE |

Free Training and Installation Service

24/7 Whatsapp Help |

| MAINTENANCE | Daily, end-of-work, weekly, monthly, 6-monthly and annual maintenance is done. |

|

OPTION

LIQUID FILLING GRANULAR PRODUCTS |

With Liquid Volumetric filling system, Ketchup, Mayonnaise Powder, Tahini, Disinfectant, Fruit Extract Syrup, Olive Oil, Liquid Detergent, Honey, Jam, Chocolate, Medicine, Shampoo etc. With Liquid Volumetric filling system, Ketchup, Mayonnaise Powder, Tahini, Disinfectant, Fruit Extract Syrup, Olive Oil, Liquid Detergent, Honey, Jam, Chocolate, Medicine, Shampoo etc.It makes automatic filling and packaging between 1 ml and 40 ml. It is a ready-made sachet type filling and packaging machine for granular products. It packs products such as seeds, grain spice, dragee. |

Powder filling packaging machine Software, Electricity, Automation, service, spare parts, all processes such as production are done within our company. In the face of problems that may occur in the machines in these matters, our company intervenes without interrupting the production. In these areas, our company does not find it appropriate to work with suppliers. For the continuity of its customers' production processes, our company always offers itself an experienced, knowledgeable and prepared problem solving approach.

The purchase of raw materials and semi-finished products such as iron, steel, aluminum, stainless, electrical, automation materials, pistons, bearings, which we use in production, changes in parallel with the daily exchange rates. You can quickly get up-to-date price information from our Whatsapp line.